An estimated 25 million miles of underground utility lines span the country's landscape. With a growing population, the need for reliable service has never been more in demand.

Once the equipment has been installed, roadways and patch areas must be restored to appropriate standards. This is where a partner you can trust is critically in demand.

For over 30 years, we've delivered quality service to our partners in the utility sector. As a member of the Strickler Corporation, our priorities and resources are aligned to deliver more value to you.

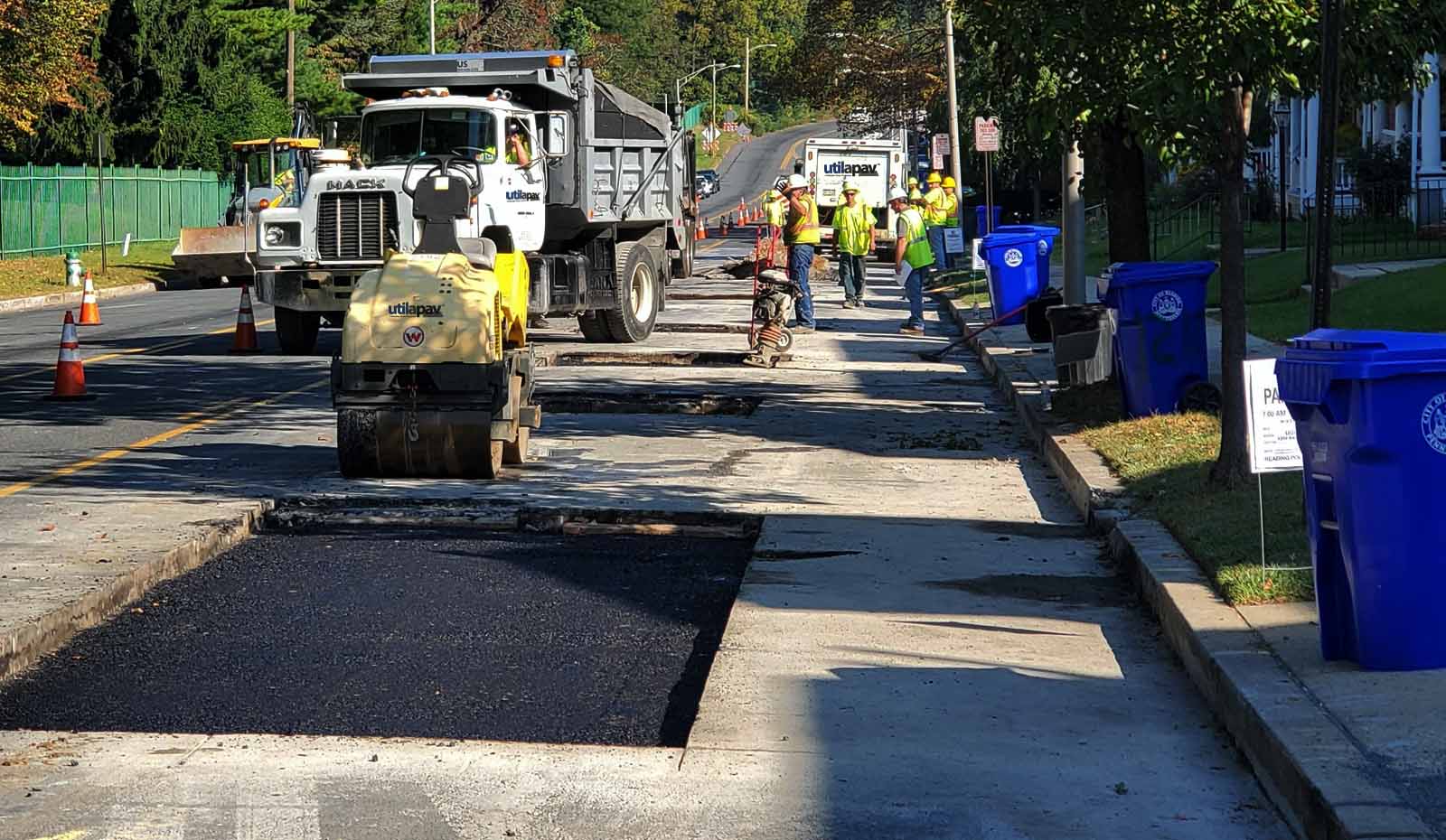

Unlike most Asphalt Paving Providers, Utilapav® exclusively provides service to the Underground Utilities market. Accordingly, utility service partners have seen the value of working with us as a single resource, dedicating people and equipment to complete their projects. At Utilapav®, our positioning advantage allows us to self-perform without sacrificing quality, due to non-utility related commitments.

Through coordination and rigorous investigation, we locate and map out the logistics of our routes and staffing daily.

Our Utilipav® Footage +Tonnage method uses automated tools that adapt to unexpected challenges, which gives our customers peace-of-mind in knowing that we have our affairs in order to deliver on our promises.

For accuracy and measurement, we follow our work with an additional Double Check inspection that verifies all work has been completed to our standards and to ensure all information is accurately relayed to our customers.

Following the installation of utility service equipment, Our saw crew locates the area that houses the section that requires patching.

Once the saw cuts are complete, we excavate and remove portions of the road to clear the area for installation of asphalt base.

Our team delivers the materials to fill the patches for proper restoration. Once the specified material has been set, our paving crew lutes and sets the patch to proper grade.

Proper compaction and sealing is critical to our process. Time and attention to detail play a critical role when manipulating hot asphalt.

Similar to "icing a cake", our rolling compaction process is continued to even out the patches with the road for smooth and safe travel. Once complete, appropriate markings and quality checks are performed.